Well apart from the battens and trim, the back end of the galley is now complete!

I have run the 12v electric supply to the gas oven (ignition only) and at the end of the day gave all the bare timber one coat of protective varnish.

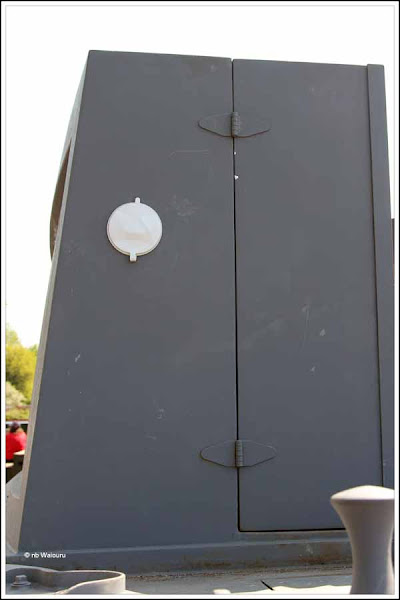

The gas oven is a very snug fit which has enabled Richard to construct a good size cavity above.

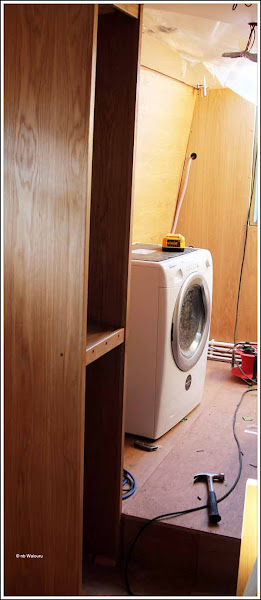

The pantry opposite will have a pull-out vertical drawer in the bottom half and adjustable shelves in the top half. The top half will also have a cupboard door.

I spent much of the morning assembling and fitting the drawer mechanisms under the galley cupboards. These replace the kickboards and allow Jan to use what would otherwise be a wasted void.

Richard had done his financial calculations and it was cheaper to purchase the drawers rather than him make them. They have the same soft close mechanism as the drawers in the top of the cupboards.

We then had a discussion about how the galley units will terminate at the saloon end of the boat.

The galley cupboards end at point A. Richard intended to make a false end using a quarter moulding (point B) with a ¾” oak veneer panel across the end of the cupboards that would conceal the cupboard feet and kickboard drawers. The 3” void between points A & C seemed to be a waste of space so I asked Richard of we could use this area by creating shelves in it for items such as spices, magazines and other odds & ends.

Tomorrow we will level and join all the galley cupboards before scribing and cutting their backs so the will fit against the lining but also provide room for the plumbing and heating pipes. The galley will then be ready for the granite bench top supplier to measure and create their templates.