This isn’t the snipe involving rifles and shooting people. Neither is it the snipe involving a sly or petty comment. It’s not the snipe involving a breed of bird. This snipe is what can happen when a piece of timber is passed through a thicknesser.

My small and cheap thicknesser has a horizontal rotary drum cutting head. either side of the head is a horizontal rubber roller. The rollers are powered and push/pull the timber through the machine and the rotating cutters remove the desired amount of timber from the surface.

Side view of the thicknesser with the feed trays folded down.

Looking up at the rotary cylinder cutter and the two rollers.

The problem with the machine is there is too much flex in the feed tables which means the timber passes through on an uneven surface.

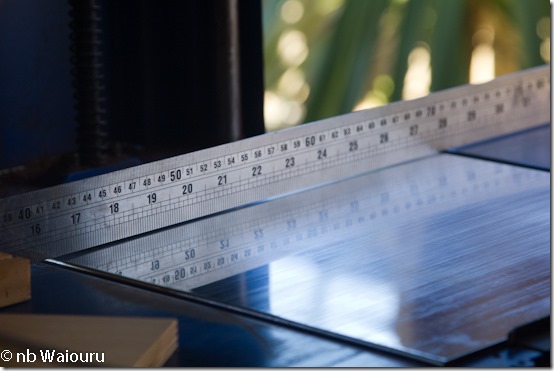

I’ve placed a steel straight edge on the surface and you can see the gap underneath the ruler.

When the timber is fed into the machine the first roller pushes down on it as the timber passes the cutter. When it reaches the next roller it gets pulled up. At this moment the cutter removes more timber than usual creating a horizontal indentation in the surface of the timber. The same thing happens at the tail end of the timber. This indentation is called ‘snipe’ and it’s a pain! With a cheap thicknesser most users simply accept snipe will occur and pass over length timber through the machine before cutting off the ends with the snipe after the final pass.

I had an idea on how I might eliminate this problem. It involved removing the entry and exit fed tables.

Then I made a longer fed table from laminated particleboard which passes right through the machine. This provides a longer approach and exit along with a firm and flat surface/

It hasn’t been a total success. The snipe has been reduced but not eliminated.

4 comments :

I saw a woodworking show on our public tv station where they talked about eliminating snipe. Their solution was to glue two 1.5" boards to each end of the board to be surfaced, that way the narrow boards pre-load the cutter head and keep it up until they drop off the end and the snipe ends up on the narrow boards.

Yes, I've also seen that method used. However I have many boards which means using that method would take days. If I get desperate I might have to use it!

Taking your idea further - could you not cut a cutting machine shaped hole into your table, and then use threaded feet to make the floor of the cutter the same as the table top? You could always have a blanking piece for when the cutting machine isn't being used?

Steve I hadn't thought of that! Probably something I'll consider when I get a workshop rather than my current very temporary arrangement.

Post a Comment