Andy fitted 95% of the Lockgate Refleks diesel stove today. He hasn’t finished screwing it to the base and the ceiling shroud hasn’t been fitted. But it’s almost done. Adam left a comment about the stove requiring a spill tray underneath and I asked Andy about this. He informed me there was no requirement to fit one under a Refleks as the catchment tray was built into the base of the stove.

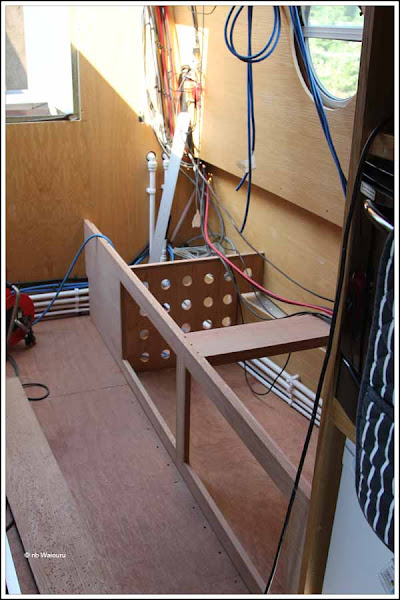

Richard and I spent the day scribing and cutting the plywood panels for the electrical cabinet above the bed in the rear cabin.

The trimmed carcase is now fixed in place, however we still have to fit the false wall panel inside to create the cable void. I also want at least one shelf. Over the weekend I had a change of heart about the layout of the instruments. Originally they were going vertically down the left side of the cabinet. I’ve decided more cabinet storage room can be achieved if the instrument layout goes across the top third of the cabinet. Some searching on Google gave me the exterior dimensions of the planned instruments and I think I’ve produced a logical and compact layout.

Meanwhile Tesco phoned Jan in response to her email complaint about the missing sugar from her last order. They were most apologetic and are refunding the cost of the sugar by crediting her card. Thank you Tesco!

More shopping from Jan. We have been existing for the last year with a very small quantity of crockery. Today she decided that as she now has a crockery rack on Waiouru she might as well buy more. To her surprise it was cheaper to purchase the plates directly from the retailer rather than through Amazon. Well, actually she saved £1 on the postage. But every £1 counts! The crockery is Corelle which is thinner and lighter than your conventional china. It’s actually a type of glassware.

This evening we are having YMCA (yesterday’s muck cooked again) for dinner. All the cooked left over veg and mashed potato’s are being combined with two tins of sardines and Jan will make fish cakes in the frypan. <yummm> The rhubarb was cooked in the pot along with some sugar. No added water. All the juice was drained off and used to make rhubarb jelly. The rest of the rhubarb was placed in the slow cooker with the crumble on top (rolled oats & brown sugar). The rhubarb eventually rose through the crumble and combined. I can envisage rhubarb crumble, jelly and ice cream for dessert. ![]()