I’ve already mentioned the planned narrowboat scene on the bedhead and today I took another major step on that part of the bed project. The scene will be freehand cut out with a router on a sheet of 4mm plywood following a paper pattern which will be glued to the plywood.

Yesterday my sister kindly let me use her home printer to produce the paper template on six A3 sheets. These are now awaiting trimming and taping together. Jan and I visited Bunnings (B&Q) where we purchased an aerosol spray can of adhesive which will be used to glue the paper to the plywood.

The completed plywood template will then be laid on the Jarrah panel and I plan to follow the grooves in the template using the router and a ‘bushing guide’. My problem is the shaft on the bushing guide that came with the DeWalt router is too big. It’s 14mm in diameter and if I were to cut a 14mm groove in the plywood template it would remove so much material that the template would fall to pieces.

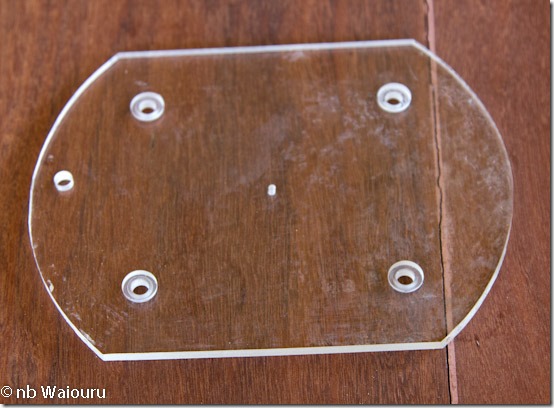

In the photo below you can see the DeWalt metal bushing guide in the Perspex base. To the right is the Porter-Cable bushing guide that came with the Leigh Dovetail Jig we purchased back in 2008.

DeWalt bushing guides are a rare as rocking horse droppings, whereas the Porter-Cable guides can be obtained in Australia. The obvious solution is to fit the Porter-Cable guide to the DeWalt router base.

DeWalt bushing guides are a rare as rocking horse droppings, whereas the Porter-Cable guides can be obtained in Australia. The obvious solution is to fit the Porter-Cable guide to the DeWalt router base.Easier said than done. I quickly discovered that at 35mm diameter the Porter-Cable guide is too small for any of my three DeWalt bases.

After looking online and realising how expensive a solution was going to be, I decided to make a base for the DeWalt router using the scrap of Perspex my brother gave me. I think the scrap is from an old railway carriage window.

After marking the outline of the base on the Perspex I cut it out using the jigsaw clamping it in place and using a scrap of timber as a guide for the straight edges.

The mounting holes were countersunk and then drilled.

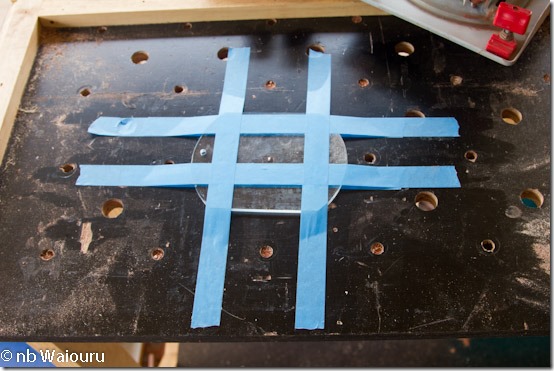

The next issue was making the hole in the middle of the baseplate. It needed to be 35mm on the bottom and 30mm on the top with a 3mm rebate. I didn’t have any 35 and 30mm drill bits so I went searching online. That’s when I noticed one of the ‘hits’ was for a Forstner bit. These are 35mm in diameter and used to drill the holes for cupboard drawers AND I remember I had one from a project back in 2009. The plan was to place the Forstner bit in the plunge router and cut a 35mm hole 3mm deep in the Perspex. But I needed to secure the Perspex so it didn’t move during the operation. I tried sitting it on two strips of paint masking tape hoping this would achieve a friction gripe. It didn’t! Then I realised I could probably tape down the new baseplate.

I was rather pleased when it worked

Next I realised I had a problem aligning the 30mm router bit with the centre of what was now a big hole. In the end I realised the solution was simple. I would screw the new baseplate to the router and cut the hole using the router.

It’s worked out perfectly.

However I’m not convinced the Porter-Cable bushing is small enough, so after even further online searching I’ve found an Australian supplier that has a set of three Porter-Cable compatible bushing for $20. The smallest of them is ¼ diameter.

2 comments :

One minor correction. Bunnings have recently bought Homebase (see

Bunnings) so Bunnings (B&Q) should read Bunnings (Homebase).

Paul you are correct. I was thinking of a UK equivalent to Bunnings (B&Q) and forgot Bunnings had purchased Homebase.

Post a Comment