The weather was supposed to be cooler today so I decided to do something about the disconnected air-con duct in the master bedroom. This is the duct I previously (and unsuccessfully) attempted to reach through the roof cavity managing to put my foot through the plaster cornice during the process. The cornice has been repaired but I still needed to do something about the detached duct.

The new plan was keyhole surgery through the roof. Like many older homes in Perth, the roof is clad in tiles. The tiles on this roof are concrete which obviously gives them some strength. However they are heavy which mean both the roof frame has to be strong and you need to be strong to move them. I paced out the location of the ceiling vent on the bedroom floor and then aligned the ladder on the guttering outside the house. My measurements were spot on and when I finally managed to move four roof tiles I could see the flexible air-con ducting in the roof cavity. It was immediately apparent that my expanded six-pack (it’s now a keg) wasn’t going to allow me to squeeze down through the narrow gap in the stringers. However there was a piece of wire attached to the roof truss holding the duct up and by repositioning the wire I was able to drop the end of the duct over the vent outlet.

By now the heat from the sun on the roof tiles was making its presence known. I have one burned elbow and a burned knee. My T-shirt also blew up my back in the wind leaving me with a touch of sunburn. But at least that’s another maintenance job completed.

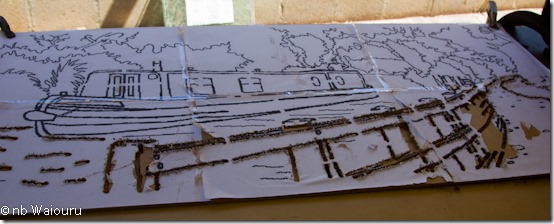

It appears the proposed course of action to router the narrowboat scene on the bedhead isn’t going to work. The idea was to make a template by cutting out the scene using a ¼” router bit. I’d then use an 1/8th in router bit with a ¼” shaft. The plan was to use one inch blocks of pine to hold the template away from the surface of the bedhead. The ¼” shaft of the router bit would be guided by the ¼” grooves in the template and the 1/8th inch tip would cut the final outline in the bedhead.

After cutting some of the template I’ve realised it’s likely the ¼” grooves are going to be too wide and the template will fall into pieces. It appears I may have to cut the outline freehand.

Meanwhile, I need another cool day to pull the dash out of the 4x4 and install the wiring looms I’m made. Once the wiring is complete I can install the 2 way radio and the vehicle will be finished.

No comments :

Post a Comment