It would be rather nice if some of those narrowboat bloggers would send some of that weather this way. The temperature at home has been over 30°C for the last 10 days and the house air conditioning unit is now murmuring about industrial action. When it’s cold you can add more clothes, but when it’s hot there’s only so much you can take off before scaring small children and old ladies!

I’ve been doing more work on the car. Not full-time as the sun on the garage roller door turns the garage into a furnace.

My brother kindly gave me a piece of box tube steel and I then used our angle grinder to cut out a strip of steel to make a mounting bracket for the 175A Anderson plug which will supply power from the 4x4 alternator to the trailer battery. I’ve ‘over engineered’ it because the alternator is rated at 100A and probably only produces around 70A. So at 175A the plug is more than capable of taking the maximum electrical load.

I filled the back of the plug with silicon to reduce water egress and have the red cap on the front to keep out dust and water (I hope)

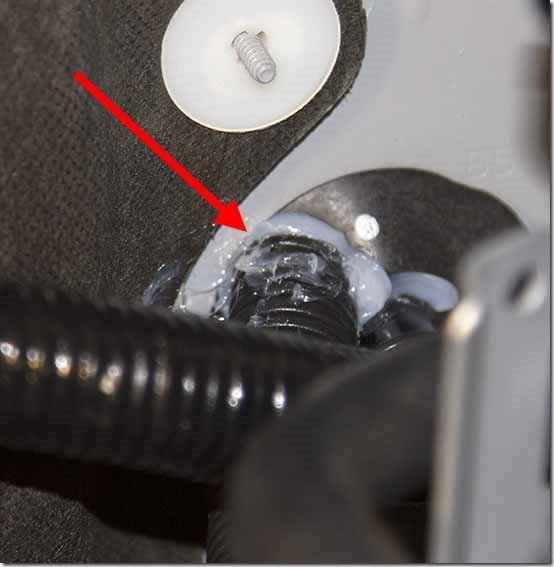

With the rear of the vehicle complete I turned my attention to routing the wires into the cabin. There is a rubber cable duct grommet on the passenger side firewall, however there wasn’t sufficient room for all my additional cables. This was solved by cutting a slit in the grommet for the cables. The cables were sprayed with silicon to ease their passage through the slit. I didn’t pull through the final 4 inches until I’d given everything a good covering of silicon sealer. the final part of the cables was the pulled though and tension applied to the cables inside the cabin whilst the silicon set.

Wires waiting to go through the grommet

All sealed up

Whilst the silicon sealer was setting I mounted the automatic resetting circuit breaker which goes in the positive feed cable to the trailer electric brake controller. I was concerned about the bare terminal studs and needed to find a location where they would be protected. Eventually I found a spot adjacent to the battery underneath the mudguard frame.

All you can see of it are the mounting bolts.

Then I turned my attention to fitting the dashcam to the front window along with the aerial for the tyre pressure management system (TPMS). The wires were tucked under the 4x4 headlining (an easy task). To route them down to the dash I removed the trim off the driver window pillar.

By now it was just too hot to continue.

A final thought regarding the blacking on Waiouru. We opted for a two pack epoxy over the standard stuff and it proved to be very successful. The boat had two full coats and a 3rd coat 30cm above and below the waterline. During three winters we broke ice and the blacking wasn’t damaged during these movements. I attribute this to three possible reasons

- The quality of the product

- Jan and I applied the blacking and had a vested interest in ensuring it was done properly

- The blacking was applied approximately four months before Waiouru was launched allowing plenty of time for it to cure.

No comments :

Post a Comment