Yesterday I visited my retired, wealthy brother (he has two wives both still working) and borrowed his portable gas torch and a pot rivet gun. He had three rivet guns to select from. I guess you can own three if you are wealthy! Whilst he’s wealthy I think he’s also foolish. Years ago an Iranian acquaintance told me you should have an odd number of wives. Apparently even numbers gang up on you!

Now to the solar panels.

I realised it wasn’t going to be a simple job to pot rivet the hinges when I noticed the solar panel extruded aluminium frame was double skinned. This was rectified by drilling larger diameter holes in the inside face. The hinges were then fitted without much difficulty.

On the reverse side you can see the larger diameter holes

I had marked out the new locations for the catches on the opposite edge of the panels and then realised the screw holes in the catches exactly lined up with the edge of the solar cells. Had I proceeded the holes and/or screws would probably have short circuited the cells destroying my panels. I need to purchase different securing catches.

These two original catches will be kept for a future project

The panels now fold in the opposite direction with the cells facing each other when closed for storage.

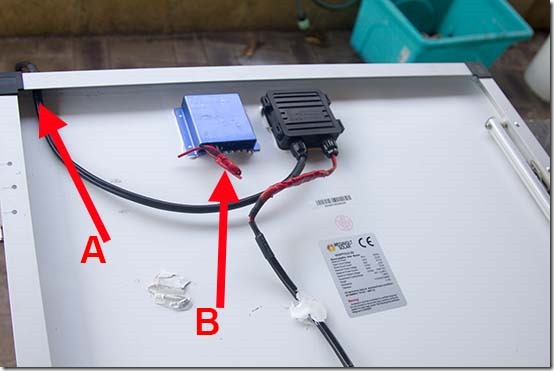

I needed to relocate the cable that connects the two panels. This was done by drilling holes in the top corner of each panel. (arrow A below). I also disconnect the solar controller (arrow B) as it’s as useful as a chocolate teapot. The wires were re-joined with crimped spade connectors and then covered with heat shrink to prevent them loosening.

This following photo shows how I made the cable connection between the two panels. The rough edges of the holes were smoothed and I also added two layers of heat shrink in an effort to prevent the cable being damaged.

The next task was to solder Anderson Plugs to the end of the extension cable and the bulldog clips. I think it’s better to have the 5 metres of cable separate to the panels.

This morning another courier driver delivered two more packages. The first is the Projecta DC to DC charger which also has an integral MPPT solar controller. It’s a three stage charger with a maximum output of 25 amps. That output is insignificant compared to the charging system on Waiouru. But then our battery bank was 900ah on Waiouru and the trailer will only have 150ah of capacity. However the Projecta does have the MPPT solar controller function. I’d identified three suitable chargers, RedArc, CTek and Projecta. They all had similar specifications so I purchased the cheapest.

The second package contained the Projecta Low Voltage Disconnect unit. The Projecta Charger is fitted before the battery (obviously) whilst the low voltage disconnect fits between the battery and the load. It’s name describes its function. The unit monitors the battery state of charge and disconnects the load from the battery before the battery can be drained to a damaging level.

There are two things that can now be done. Using my wealthy brother’s gas torch I can modify the 12V portable air compressor so it can be plugged into the 4x4. I can also do a temporary connection between the solar panels, Projecta charger and the 150ah AGM battery to test everything works.

1 comment :

Nice work Tom not sure your brother is wealthy just a hoarder!

The double heat shrink I have my doubts about over the hinge. I would have had a grommet to, to pass the cable through,

Cheers

Ade

Post a Comment